Efficient HVAC system management is vital for maintaining comfort, energy efficiency, and indoor air quality in buildings. In this article, we will explore the role of damper actuators in simplifying HVAC system control. Specifically, we will delve into the benefits of damper actuators, including Siemens damper actuators, Johnson Controls damper actuators, and Spring Return Damper Actuators. By understanding how these devices streamline HVAC system management, engineers and building professionals can make informed decisions to optimize system performance.

Understanding Damper Actuators

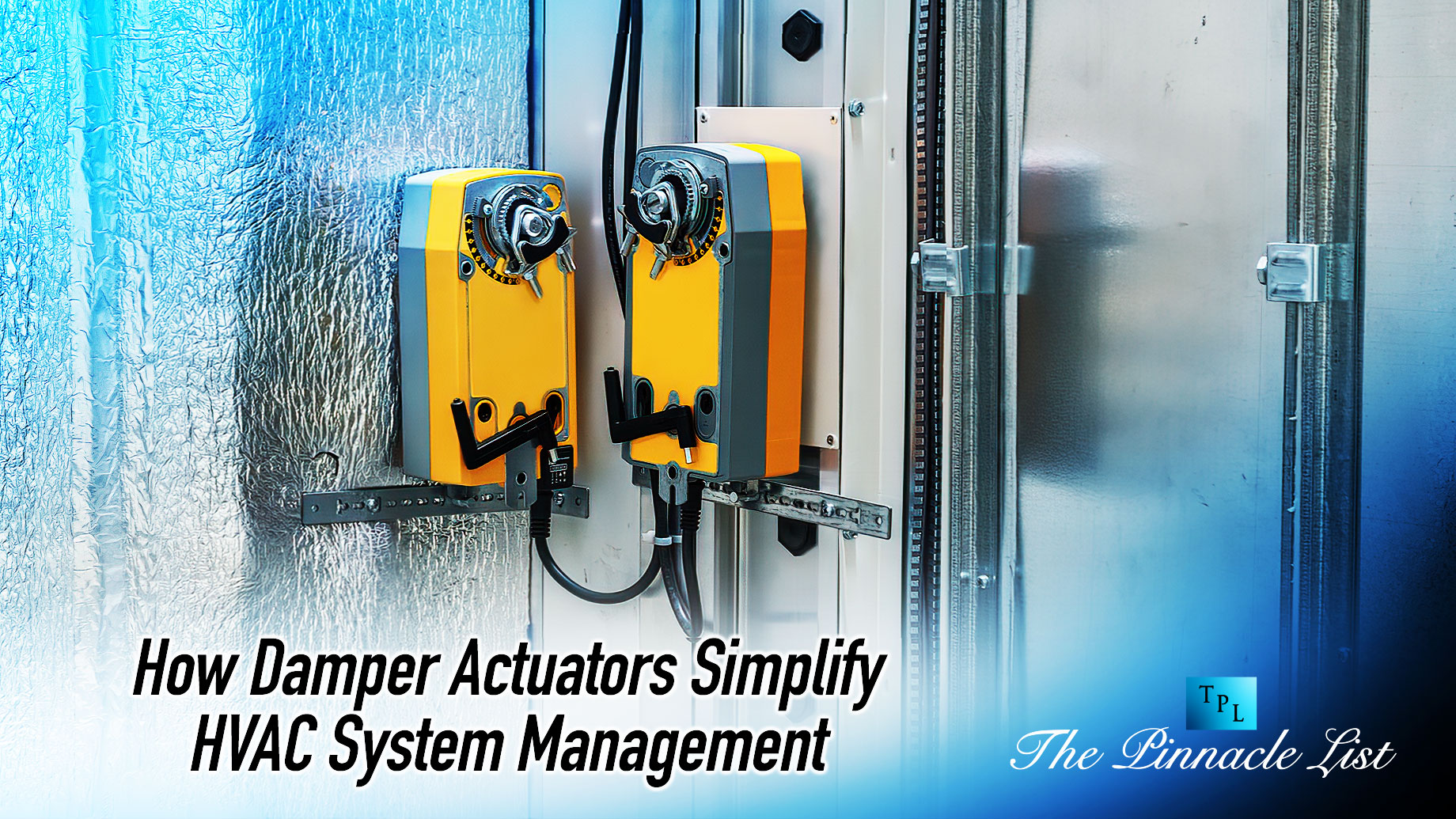

Damper actuators are essential components in HVAC systems that control the opening and closing of dampers to regulate airflow. These devices are designed to automate the manual adjustment of dampers, providing precise control over ventilation, heating, and cooling processes. The dampers themselves are valves or plates within the ductwork that can be opened or closed to control the volume of airflow. The damper actuators contain motors that open and close the dampers on command.

They receive control signals from a central HVAC management system that monitors the temperature and ventilation needs throughout the building. The actuators then open or close the dampers to increase or decrease airflow to different areas as needed. Precise control over damper positioning allows for optimized efficiency and comfort.

Damper actuators come in several types to suit different damper and control designs. The most common types are electric actuators, pneumatic actuators, and hydraulic actuators. Electric actuators are driven by electric motors and are typically the most energy-efficient option. Pneumatic actuators are driven by the flow of compressed air, while hydraulic actuators are driven by the flow of oil or other hydraulic fluid. The appropriate actuator is selected based on factors like torque requirements, speed, precision, and the availability of a power source.

The Benefits of Damper Actuators

Damper actuators offer several advantages that simplify HVAC system management. Firstly, they provide enhanced control and precision in airflow regulation, ensuring optimal distribution of conditioned air throughout the building. By accurately adjusting dampers based on temperature, occupancy, time of day and other variables, damper actuators contribute to improved comfort and energy efficiency. The increased control allows building managers to direct air only where it is needed, reducing waste.

Moreover, these devices help maintain consistent indoor air quality by allowing effective ventilation control. The ability to precisely control damper positions means enough fresh air can be brought in and stale air exhausted to suit the needs of any space. Damper actuators also permit demand-controlled ventilation, where CO2 sensors detect occupancy levels and adjust ventilation rates accordingly. This results in a healthy indoor environment without sacrificing efficiency.

Damper actuators reduce costs through optimized system performance and minimized maintenance requirements. Their automated operation eliminates the need for manual damper adjustment, while their electronic components are built to operate for years with little servicing. Precise damper control also lessens mechanical wear and tear on other HVAC components like fans and air handlers by ensuring optimal operating conditions. Overall, damper actuators provide an inexpensive solution for improving commercial HVAC system function.

Simplifying HVAC System Control

One of the primary benefits of damper actuators is their ability to simplify HVAC system control. With user-friendly features and interfaces, these actuators enable engineers and building operators to easily program, monitor, and adjust damper positions in a convenient manner. Siemens damper actuators, for instance, offer intuitive interfaces with clear displays that simplify the configuration and troubleshooting processes, allowing for quick setup and diagnosis. Johnson Controls damper actuators are known for their seamless integration capabilities with building management systems, providing centralized and coordinated control as well as real-time data monitoring for optimal HVAC performance. Spring Return Damper Actuators offer a straightforward and dependable solution to control damper positions, ensuring consistent and reliable control of airflow for ideal system operation.

Siemens Damper Actuators

Siemens damper actuators are renowned across the industry for their superior construction and advanced capabilities. These actuators are engineered to satisfy the diverse requirements of modern HVAC systems, offering features such as precise proportional control, flexible modulating control, and even reliable fail-safe functionality. By utilizing Siemens damper actuators, HVAC engineers and technicians can ensure accurate, dependable, and fine-grained control over damper positions, allowing for highly efficient system performance and operation.

Johnson Controls Damper Actuators

Johnson Controls damper actuators are extensively recognized for their robust and durable designs as well as interoperability with a wide range of HVAC systems. These actuators incorporate innovative technologies to enhance control precision, accuracy and responsiveness. Johnson Controls provides an array of actuator models, including electric, pneumatic, and spring return options to suit the different needs of HVAC systems. By leveraging Johnson Controls damper actuators, engineers can achieve a high degree of integration and optimized control of damper positions across HVAC infrastructure.

Spring Return Damper Actuators

Spring Return Damper Actuators provide a simple yet effective solution for regulating damper positions. These actuators utilize a mechanical spring mechanism to guarantee fail-safe functionality, automatically returning the damper to a predetermined position in the event of a power failure or disruption. The spring return feature offers reassurance by maintaining the desired airflow control even during unforeseen system interruptions or outages. Engineers frequently choose Spring Return Damper Actuators for their dependability, straightforward installation, and cost-effectiveness.

Choosing the Right Damper Actuator

When selecting damper actuators for specific HVAC system requirements, engineers should consider factors such as compatibility, performance, and reliability. Evaluating the control options, feedback mechanisms, and installation requirements of different damper actuator models is crucial. Additionally, understanding the specific needs of the HVAC system, including damper size and control protocols, ensures an informed decision that aligns with the project’s objectives.

Conclusion

Damper actuators, including Siemens damper actuators, Johnson Controls damper actuators, and Spring Return Damper Actuators, play a pivotal role in simplifying HVAC system management. These devices offer enhanced control, improved energy efficiency, and optimal indoor air quality. By utilizing damper actuators, engineers can achieve effortless control over damper positions, leading to well-balanced airflow distribution and enhanced HVAC system performance. Whether it is a large commercial building or a residential application, choosing the right damper actuator is crucial for maximizing system efficiency and ensuring occupant comfort.