Advancements in technology are reshaping the industrial landscape, optimizing workflow efficiency, promoting seamless operations, and ultimately driving increased productivity and profitability. Read on to learn about innovative data analytics, intelligent lighting systems, automation options and more.

IoT and Connectivity

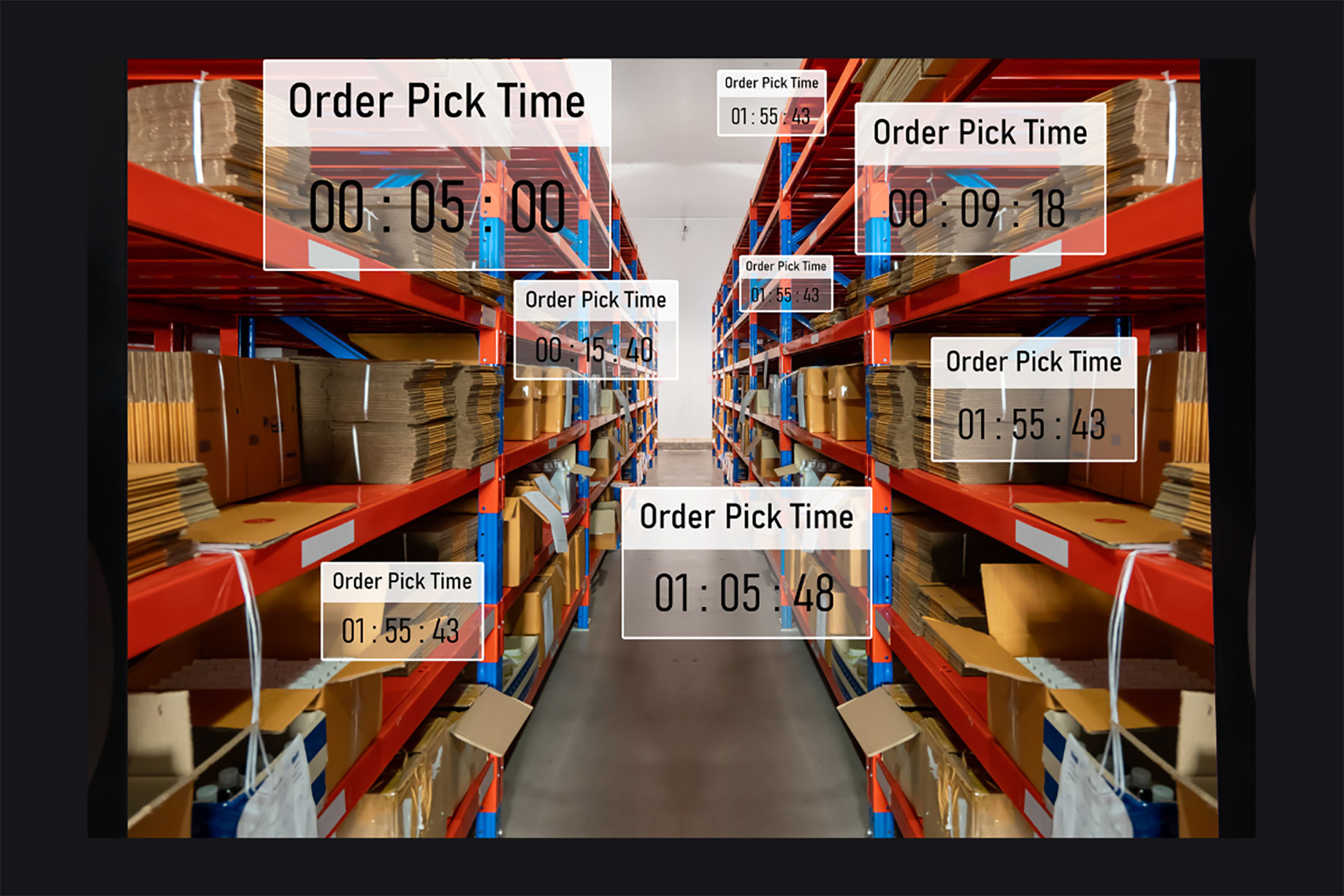

The Internet of Things (IoT) is facilitating real-time connectivity and data exchange among warehouse components. Sensors on inventory shelves, equipment, and vehicles provide valuable insights into stock levels, equipment health, and operational bottlenecks. This data-driven approach enables proactive decision-making, minimizing downtime, and optimizing resource allocation for enhanced productivity.

AI for Predictive Analytics

Artificial intelligence (AI) and machine learning algorithms are transforming warehouses into intelligent hubs capable of predictive analytics. These systems analyze historical data to forecast demand, optimize inventory levels, and predict equipment maintenance needs. By anticipating challenges and trends, warehouses can proactively address issues, reduce downtime, and maintain a competitive edge in the market.

Voice Recognition Systems

Voice recognition technology is simplifying and accelerating order fulfillment processes. Warehouse staff equipped with hands-free, voice-activated devices can receive instructions, update inventory, and navigate through tasks seamlessly. This not only improves efficiency by reducing manual input time but also minimizes errors associated with traditional paper-based or handheld device methods.

Advanced Lighting Systems

A sometimes-overlooked technology reshaping warehouse dynamics is advanced lighting – specifically, linear LED high bay lighting with optimized color temperature, brightness levels, and smart controls. Tailoring color temperature to each space helps tailor areas of a warehouse to specific needs, while adjusting brightness levels ensures optimal conditions for diverse work areas. Smart controls add a layer of adaptability, enabling real-time adjustments based on factors such as occupancy and daylight levels. Intelligent lighting not only enhances operational efficiency but also contributes to a healthier and more focused workforce, resulting in increased productivity.

Robotics and Automation

The integration of robotics and automation technologies has emerged as a game-changer in warehouse operations. Automated guided vehicles (AGVs), robotic arms, and conveyor systems are streamlining tasks such as order picking, packing, and inventory management. These technologies not only reduce manual labor but also significantly cut down on processing times, leading to quicker turnaround and improved overall efficiency.

Case Study: Amazon Fulfillment Centers

Background: Amazon, a global e-commerce giant, operates a vast network of fulfillment centers worldwide. These centers are strategically designed and equipped with advanced technologies to enhance efficiency, speed, and accuracy in order fulfillment.

Key Technologies and Strategies

- Robotic Automation:

- Amazon utilizes a fleet of robots known as Kiva robots or Amazon Robotics to automate the movement of products within its fulfillment centers. These robots bring the shelves of products to human workers, reducing the time workers spend walking and improving overall picking efficiency.

- Advanced Sorting Systems:

- Automated sorting systems are employed to categorize and route packages to their respective destinations. This reduces manual handling and speeds up the sorting process, ensuring that packages are ready for shipment in the shortest possible time.

- AI and Machine Learning:

- Amazon uses sophisticated algorithms and machine learning models to predict customer demand accurately. This helps in optimizing inventory placement within the fulfillment centers, ensuring that popular products are strategically located for faster retrieval.

- Data Analytics for Continuous Improvement:

- Amazon continuously analyzes data generated by its operations to identify areas for improvement. This data-driven approach helps in refining processes, optimizing inventory levels, and reducing errors over time.

Results

- Increased Efficiency:

- The use of robots for material handling has significantly reduced the time it takes to pick and pack items. This increased efficiency allows Amazon to process a large number of orders within a short period.

- Faster Order Fulfillment:

- Advanced sorting systems and strategic inventory placement enable Amazon to fulfill customer orders quickly, meeting and often exceeding customer expectations for fast shipping.

- Reduced Operating Costs:

- Automation and advanced technologies have led to reduced labor costs and increased overall operational efficiency, contributing to a more cost-effective fulfillment process.

- Enhanced Customer Experience:

- Faster order processing and accurate order fulfillment contribute to an improved customer experience. Customers receive their orders promptly, and the likelihood of errors in shipment is minimized.

The success of Amazon’s fulfillment centers serves as a benchmark for how a combination of robotics, automation, data analytics, and advanced systems can significantly improve productivity in a warehouse setting. These innovations collectively contribute to the optimization of workflow efficiency, the promotion of seamless operations, and the enhancement of profitability in industrial setups. As warehouses continue to embrace smart setups, they position themselves at the forefront of efficiency and competitiveness in the industrial sector.