Plywood is a panel-shaped sheet material that is manufactured from thin layers of wood veneer. These thin layers are known as plies. The plies are glued together with other plies having their wood grains rotated up to a 90 degrees angle to one another. Hence, this type of wood is an engineered product.

Plywood factories blend resin and wood fiber sheets to form a composite material out here. The alteration of grain known as cross-graining is done to reduce the tendency of the plywood to split when nailed at the edges. As a result, it reduces shrinkage and swelling that occurs due to change in temperature.

What are the types of plywood?

1. Hardwood plywood

The plywood is prepared from gurjan wood or birch wood that is a type of teak. If all the veneers are prepared solely from hardwood, then the plywood is called 100% hardwood plywood. Such plywood is expensive.

2. Softwood plywood

This type of plywood is made from cedar, SPF (Spruce-pine-fir), or Mango wood.

3. Flexible plywood

The plywood is also known as flexiply because it is not stiff and can be bent in either direction and even rolled up. This type of plywood is commonly used for making round-shaped furniture.

4. FR Grade plywood

Such plywood has the distinct characteristic of being fire-resistant. Hence, it is commonly used in malls, shopping complexes, public theatres, restaurant kitchens, and any other place where there is a threat of a fire. The fire-resistant property of such plywood comes from the chemical coating on its surface that delays the burning process.

5. Marine Grade plywood

Such plywood is used in the building of boats and ships because it is resistant to water. It is also termite-resistant and borer-proof.

6. Structural plywood

It serves a purpose in construction where structural stability is crucial.

7. Concrete Shuttering plywood

The plywood is used to help settle the concrete into a building. A variant known as film-faced shuttering plywood has a very shiny phenolic film on the surface. It prevents the concrete from sticking to the plywood.

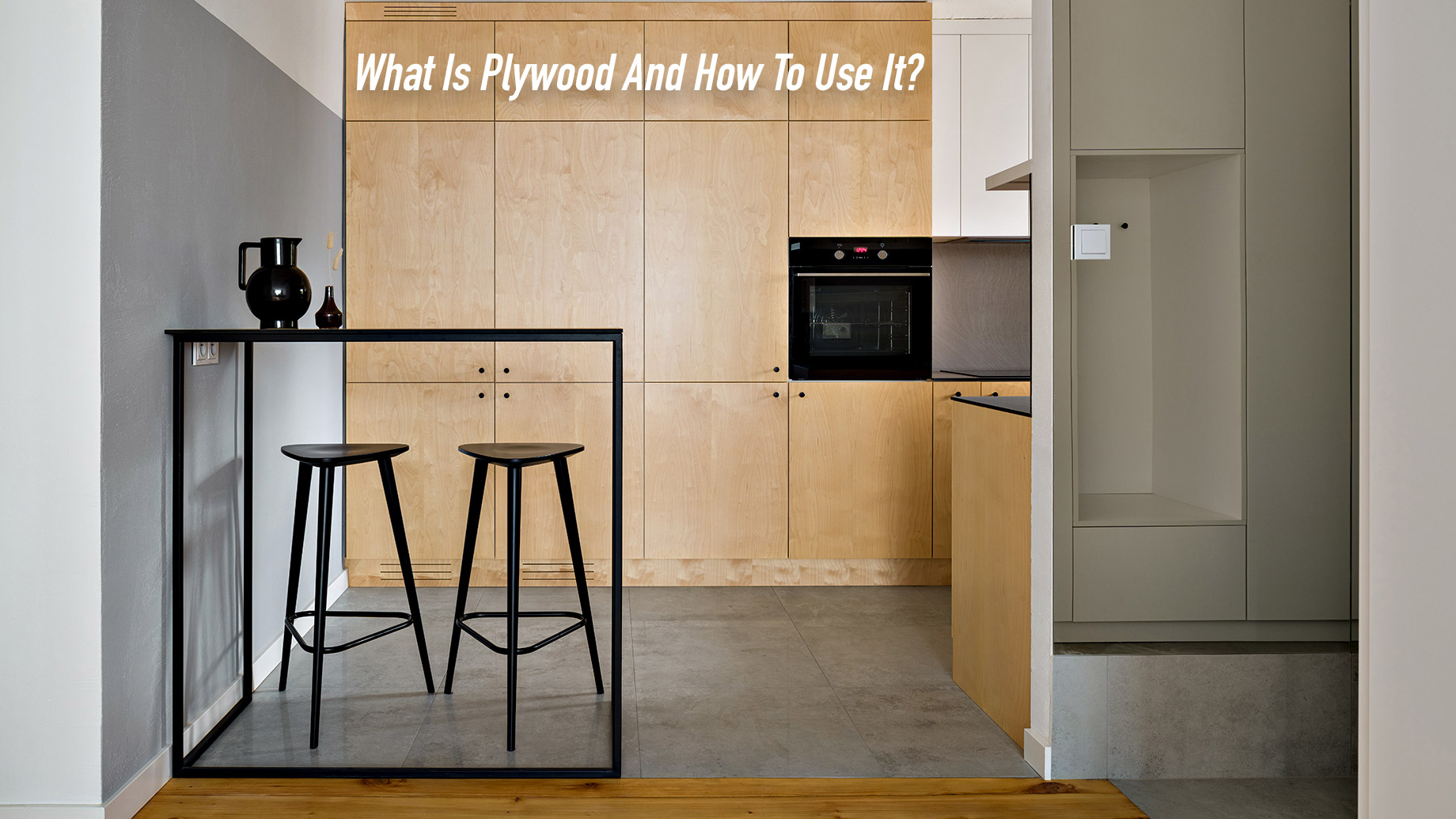

8. Cabinet Grade plywood

This premium quality plywood features smooth surfaces and consistent appearance, making it ideal for visible applications like kitchen cabinets, built-in furniture, and fine woodworking projects. Cabinet grade plywood often comes prefinished, saving time and ensuring a professional look.

How is plywood decorated?

Plywood is decorated with the following treatments.

1. Laminates

One of the most popular laminates Sunmica is a blend of paper and plastic. The laminate is glued to the plywood surface. Laminates offer a variety of colors, patterns, and textures. Lamination is the most preferred way of decorating plywood furniture and wooden panels.

2. Paints

It has been one of the most common ways of protecting wood and enhancing its beauty for centuries. It is a rather cost-effective alternative to lamination or veneers. Also, a large number of wood colors are available if one chooses to paint their furniture.

3. Wood polish

Wood polish is specially designed for application on wooden furniture. It serves best on quality hardwood such as teak. Carpenters often use the wood polish of darker shades on certain parts of furniture, usually the underside of tables and inside planks of beds.

4. Veneer

A wood veneer is a thin slice or sheet of quality wood such as a teak. The veneer is glued over the plywood to enhance its beauty. It is a great way to upgrade your furniture since most casual observers cannot differentiate between solid teak furniture and veneered plywood. However, wood veneer is the most expensive way of treating plywood.

General uses of plywood

- Plywood is used when using a strong material is indispensable because it is a high-quality layered wood material.

- Different types of plywood are resistant to bending, splitting, fire, breaking, and warping. Hence, it is highly suitable for the construction and furniture industry.

- It is a good choice for outdoor usage.

- It serves a great purpose in the space and aviation industry.

- Marine-grade plywood is used in the shipping industry.

- Flexiply is used for curvy furniture as it bends easily.

Uses of softwood plywood

- Spruce plywood is commonly used for floors, walls, and roofs in home construction.

- Wind bracing panels

- Indoor bodywork of high-end luxury vehicles

- Packing boxes

- Fencing

- Concrete shutting panel

- Ready to paint surfaces for construction

Uses of hardwood plywood

- Phenolic resin-coated plywood is commonly used as a ready installation component.

- In parks and in community systems

- Certain types of floors

- Vehicles

- Scaffolding materials.

- In wind turbine sheds, and insulating boxes for liquefied natural gas carriers.

Uses of birch plywood

- High-end loudspeakers

- Die Cutting Boards

- Parapet support structure

- Signs and fences for advertising use.

- Musical Instruments

- Playground Equipment

- Sports Equipment

Uses of tropical plywood

- Common Plywood

- Concrete Panel

- Structural Panel

- Flooring

- Lamination Board

- Laminated Lumber

Since plywood is quite cost-effective and lightweight, it is often used for making film sets and stage sets. It is also used for building skateboard ramps due to its smooth finish and flexible nature. So, make good use of this wonderful engineering marvel while beautifying your home.